Release time:2022-03-14

Plastic shell production process 1: at the initial stage of the plastic shell production process, what we need to do is to prepare materials. In the process of material preparation, what we need to do is to check the quality of plastic shell materials and determine the types of materials used. Because there are usually more choices of plastic shell materials, we must make accurate choices.

Plastic shell production process 2: after selecting materials, the plastic shell production process will come to the mixing and drying process. In this process, many friends do not know the specific function. In fact, the essence of mixing and drying is to remove the moisture in the material and reduce the occurrence of defects in the plastic shell injection molding process. If the moisture in the material cannot be reduced by 0.02%, irregular crazes will appear on the surface of the finished plastic shell, which will have a great impact on the appearance of the plastic shell.

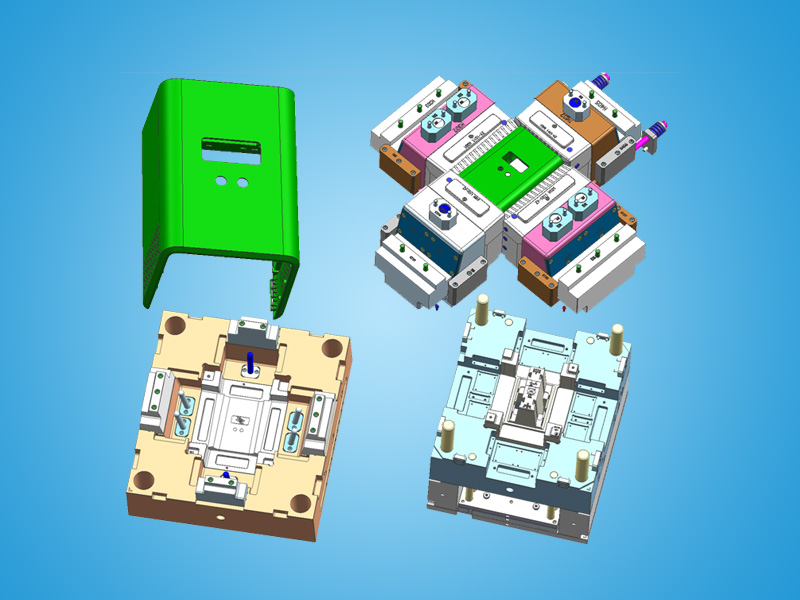

Plastic shell production process 3: the important production process of plastic shell must be injection molding process, which determines whether the plastic shell meets the standard process. If you want to process a good quality plastic shell, you must control the temperature, mold, injection method, injection speed and other factors, so this process also needs to be carefully completed.

Plastic shell production process 4: the plastic shell comes to an end with the completion of injection molding. What we still need to do is to complete the quality inspection of the plastic shell, and then pack it out of the factory.